KVP Multiformvac VP3 Vacuum Press Machine

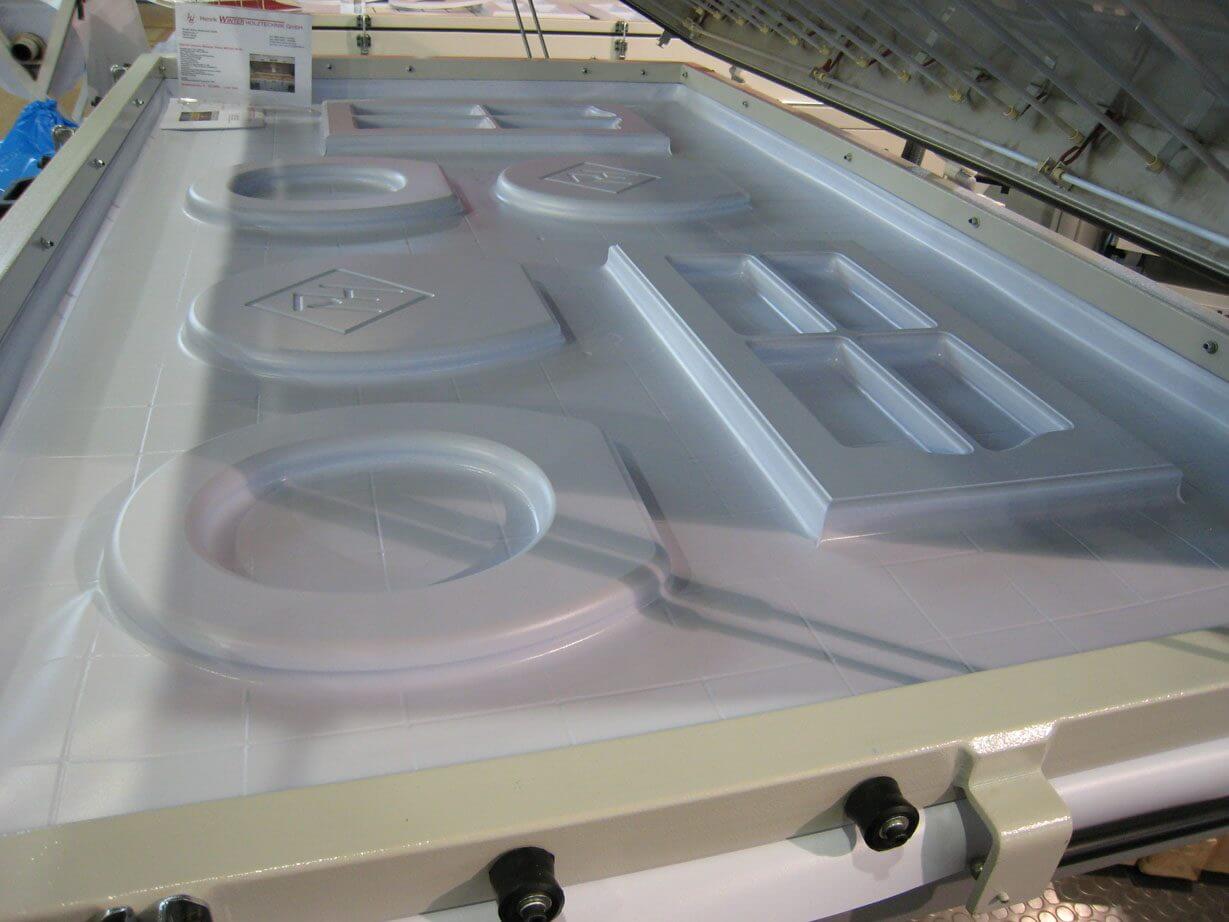

KVP Multiformvac VP3 Vacuum Press Machine is a multifunctional, hot-cold vacuum membrane press machine used for 3D lamination, layer bonding and bonding various coatings on formed surfaces. Multiformvac is the ideal combination of two pressing techniques in one simple machine. PVC / high-gloss PVC / PET / Thermoplastic Foils can be applied 3Dly to MDF cabinet doors, etc. without the use of membrane. is pressed.

Categories: Furniture Machine, Press Machine

Description

Areas of Use

Complex shapes, professional layer bonding (sandwich technique):

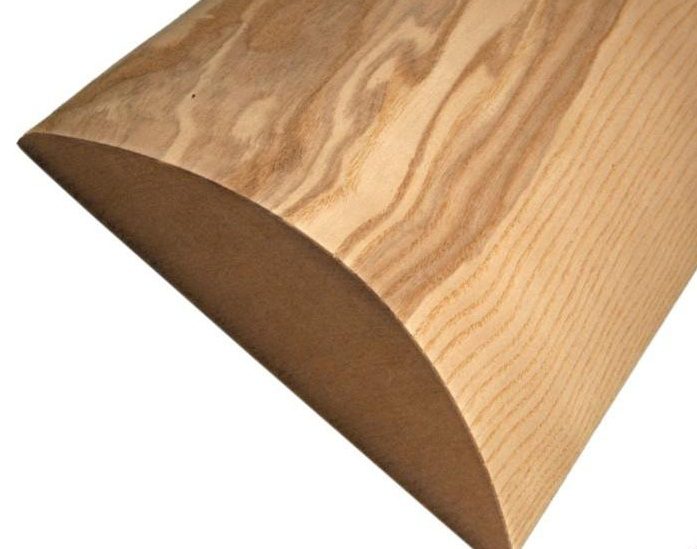

- You can produce curved furniture pieces, interior decoration pieces, kitchen countertops, parts for boats-yachts, trains, caravans and buses.

- Cover the formed workpiece with wood veneer or laminate PET, PVC, ABS, leather, paper etc. you can cover it with materials.

- You can produce various profiles and aesthetic interior design solutions for furniture production.

- You can produce table, bench and coffee table tops, work surfaces, coffin production, wall and ceiling profiles.

- You can obtain 2D and 3D products from thermoplastic materials. Ideal for shaping mineral-based materials (Corian, Himacs, Avonite, Staron, Marlon) and materials such as ABS and acrylic.

Technical Information

- Electrical Connection: 380-400 v / 50-60 hz

- Energy Consumption: 31 kW/hour

- Dimensions: Width 160 cm x Length 310 cm x Height. 170 cm

- Table Internal Dimensions: 130 cm x 290 cm

- Vacuum Pump: 1.5 kW / 63 m3/hour

- Operation Control: Automatic - Manual

- Membrane Thickness (Optional): 2 mm Silicone