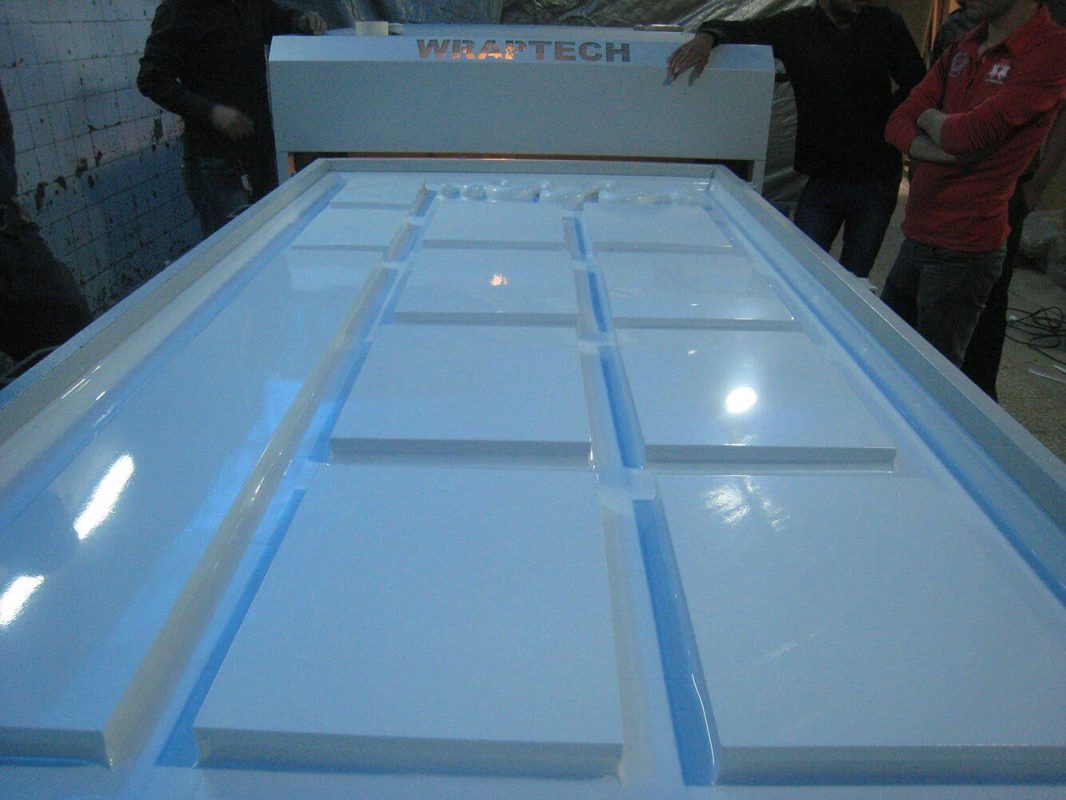

Maxivac T2-T3 Vacuum Press Machine

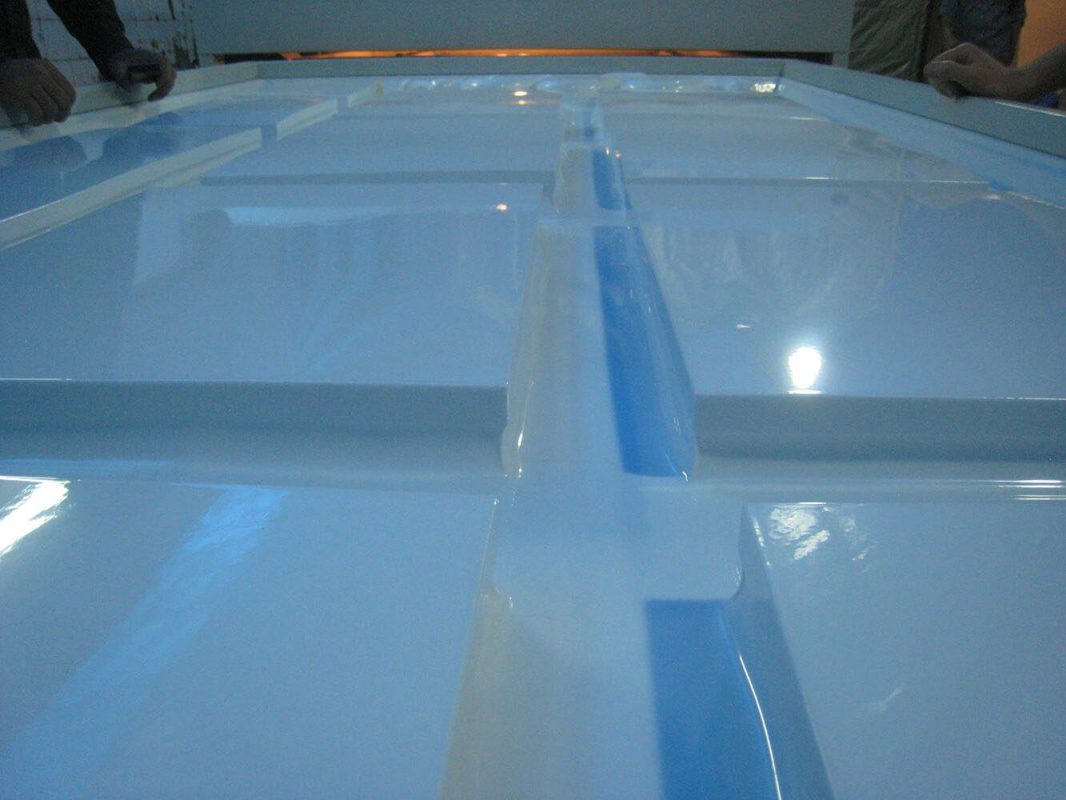

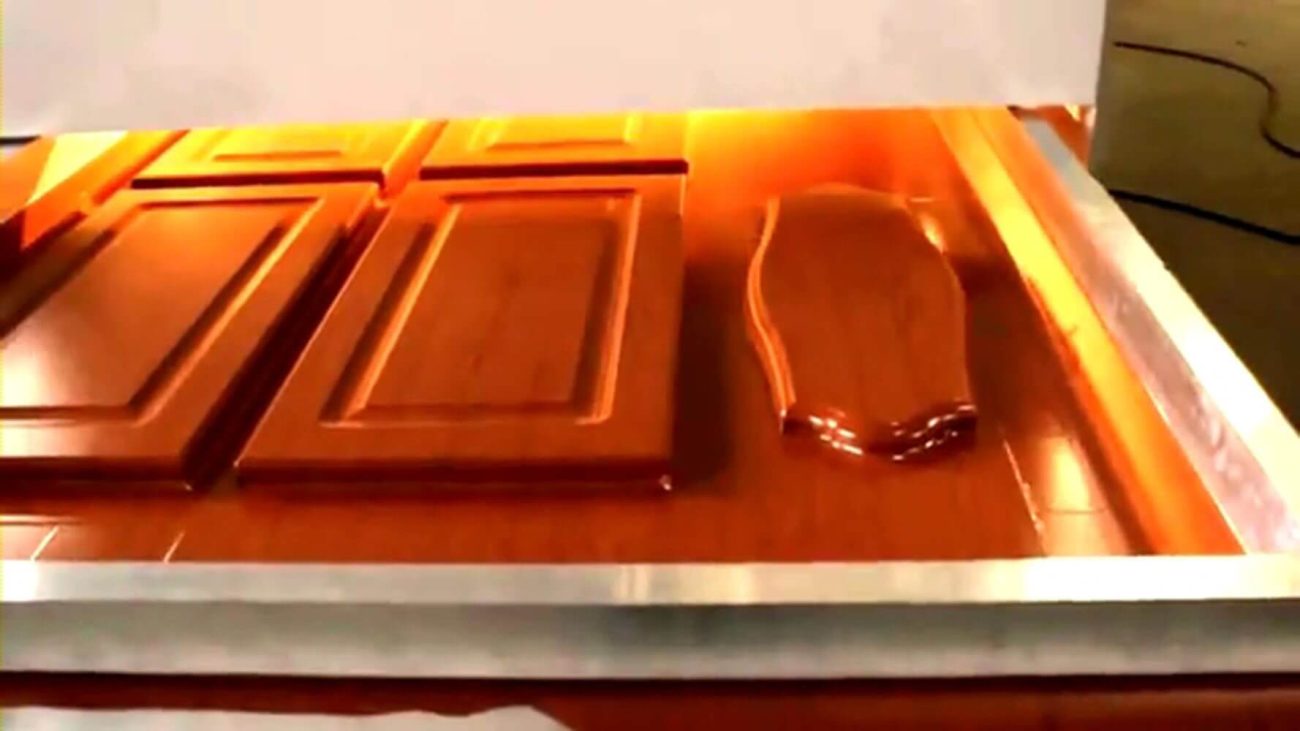

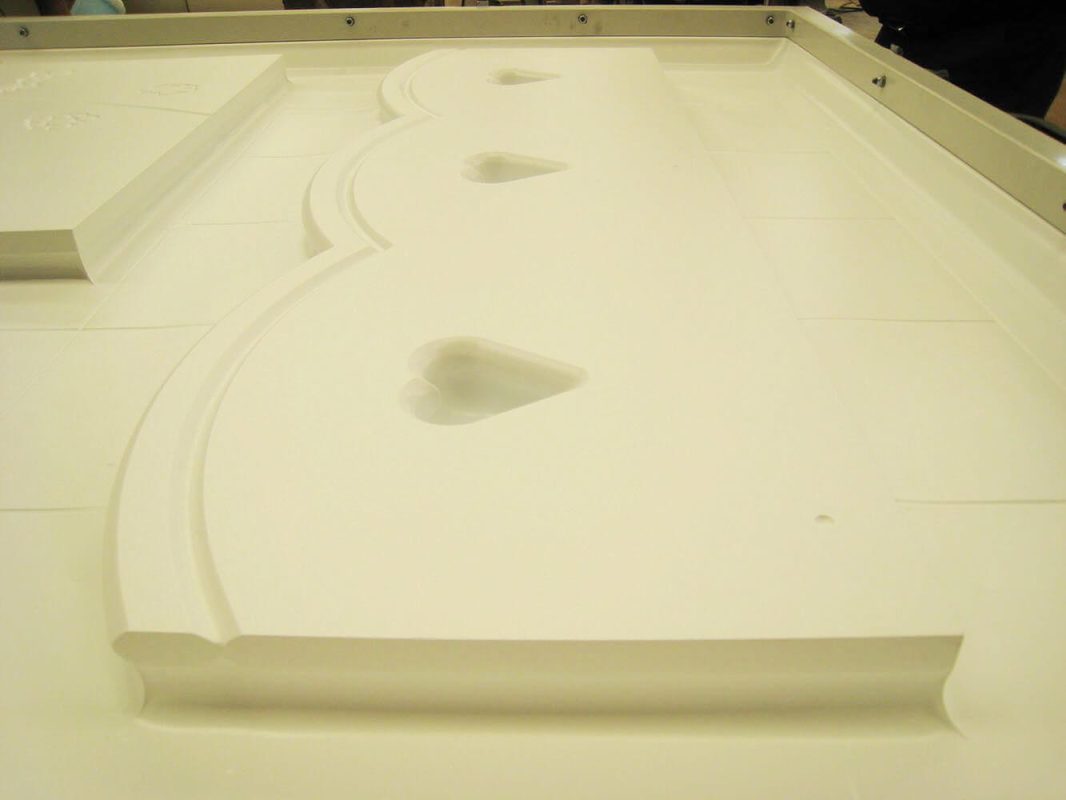

Maxivac T2-T3 Vacuum Press Machine is a hot vacuum membrane press machine used for 3D lamination and bonding various coatings on low-form surfaces. PVC / high-gloss pvc / PET / Thermoplastic Foils are applied 3Dly to MDF cabinet doors, etc. is pressed.

Categories: Furniture Machine, Press Machine

Description

Areas of Use

- Maxivac T2-T3 has been our most popular model in Turkey since 2003.

- It is a simple, economical machine for those who think that they can produce their own caps and also produce the caps of manufacturers around them on a contract basis.

- Wood cladding operations can be done by installing a membrane and opportunities are offered.

- It can be produced with 2 or 3 tables according to your request. Table dimensions may vary depending on your preference.

- For example, you can consider choosing a 140x140 cm middle table to handle your leftover or damaged single lid work with minimal waste.

- You can consider covering a table with 125 cm wide foils and save money.

- If you want to avoid long delivery times, high cover costs, easily complete a defective or missing cover and achieve flexible productivity, here is the solution.

- Your helper at hand for your work such as kitchen and bathroom cabinet doors, furniture parts, etc. ECONOVAC-2 units are inexpensive and easy to use. Even if you only produce your own products, rapid amortization is guaranteed. You'll get your covers at almost half the price.

Technical Information

- Electrical Connection: 380-400 v 50-60 hz

- Energy Consumption: 41 kW/hour (Energy Consumption: Approximately 1 kW for 1 Table Work)

- Dimensions: Width 170 cm x Length 584 cm x Height. 160 cm

- Number of Press Tables: 2 or 3 Tables (Table Sizes May Also Be Different)

- Table External Dimensions: 140 cm X 270 cm

- Table Depth: 48 mm

- Vacuum Pump: 1.5 kW Oil Ring Vacuum Pump

- Vacuum Pump Power: 65 m3/Hour (Provides 1 kg Pressure per Square Centimeter)