Midivac Vacuum Press Machine

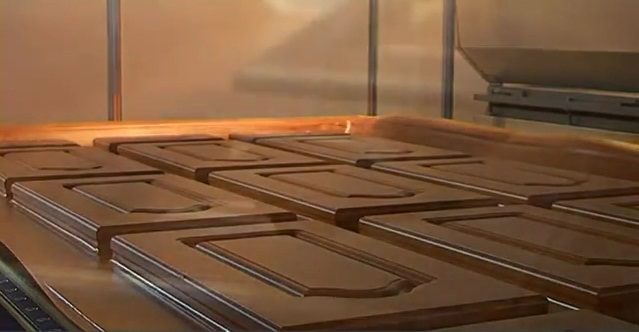

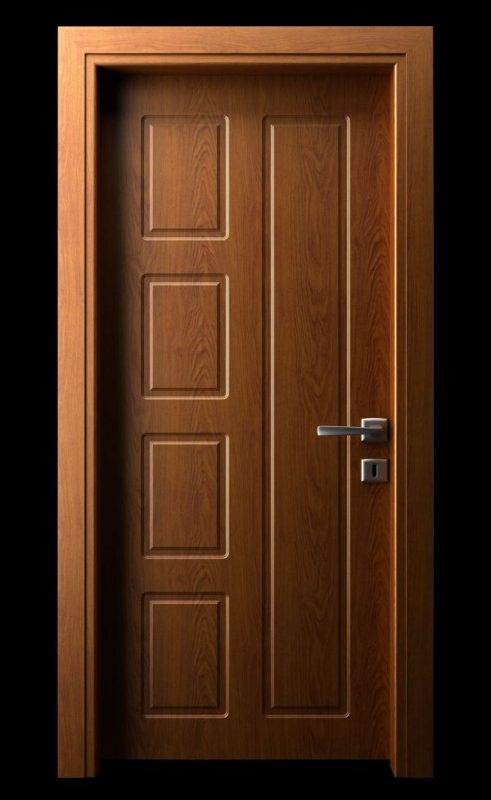

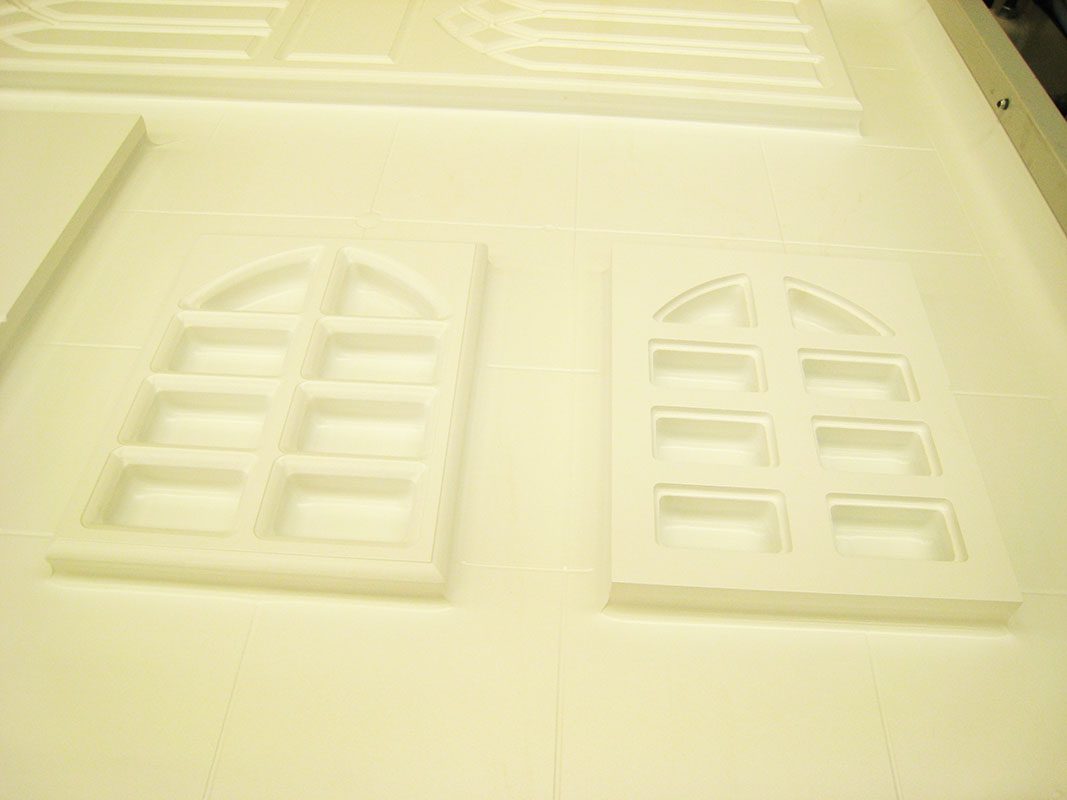

Midivac Vacuum Press Machine is a hot vacuum membrane press machine used for 3D-Lamination and bonding various coatings on low-form surfaces. Without the use of membrane, PVC / high-gloss PVC / PET and Thermoplastic Foils are pressed 3Dly onto MDF cabinet covers, doors, etc.

Categories: Furniture Machine, Press Machine

Description

Areas of Use

- MIDIVAC is a simple-to-use, economical machine for those who want to produce their own covers.

- It can be produced with a single or two tables, or one of the tables can be of a different size. It also allows for wood cladding works by optionally installing a membrane.

- If you want to avoid long delivery times, high cover costs, easily complete a defective or missing cover and achieve flexible productivity, here is the solution.

- Your helper at hand for your work such as kitchen and bathroom cabinet doors, furniture parts, etc. DOOR-FRONT/B units are inexpensive and easy to use. Even if you only produce your own products, rapid amortization is guaranteed. You'll get your covers at almost half the price.

Technical Information

- Electrical Connection: 380-400 v 50-60 hz.

- Energy Consumption: 37 kW/hour (Energy Consumption: Approximately 1 kW for 1 Table Work)

- Dimensions: Width 250 cm x Length 550 cm (350 cm for Single Table Machine) x Height. 145 cm

- Number of Press Tables: 1 or 2 Tables (Table Sizes May Also Be Different)

- Table External Dimensions: 140 cm X 240 cm

- Table Depth: 48 mm

- Vacuum Pump: 1.1 kW Oil Ring Vacuum Pump

- Vacuum Pump Power: 40 m3/Hour (Provides 1 kg Pressure per Square Centimeter)