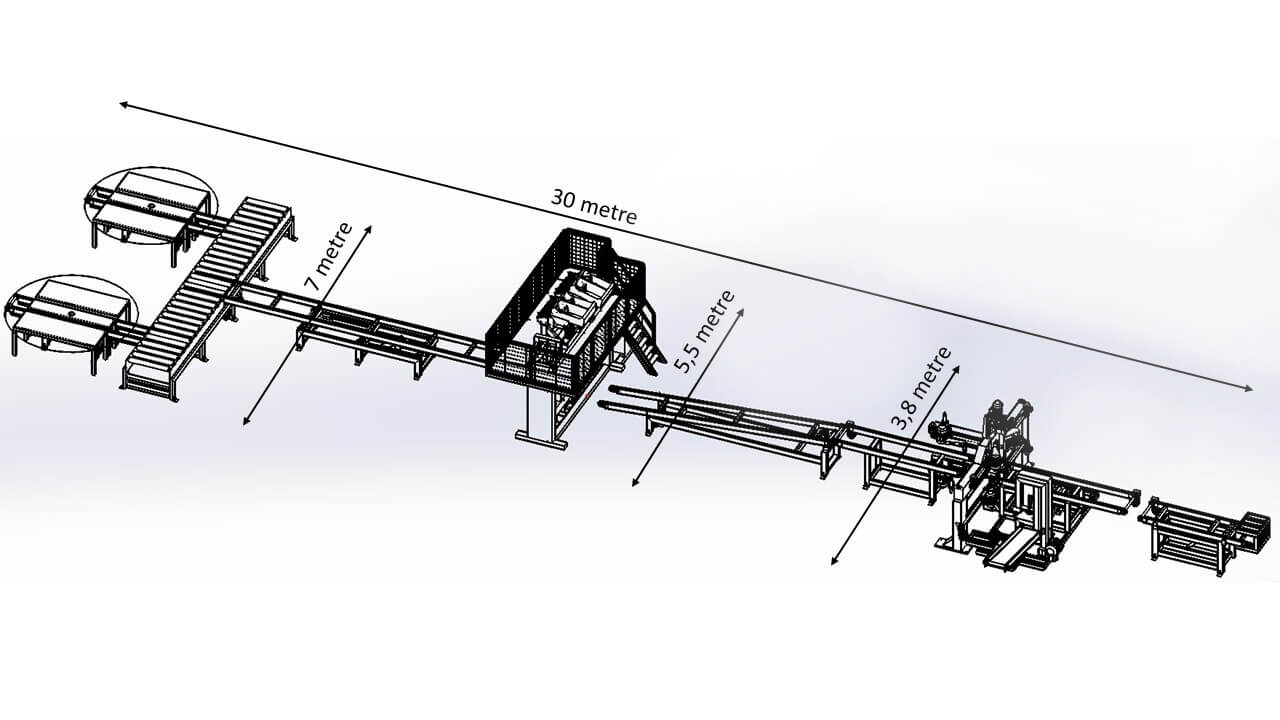

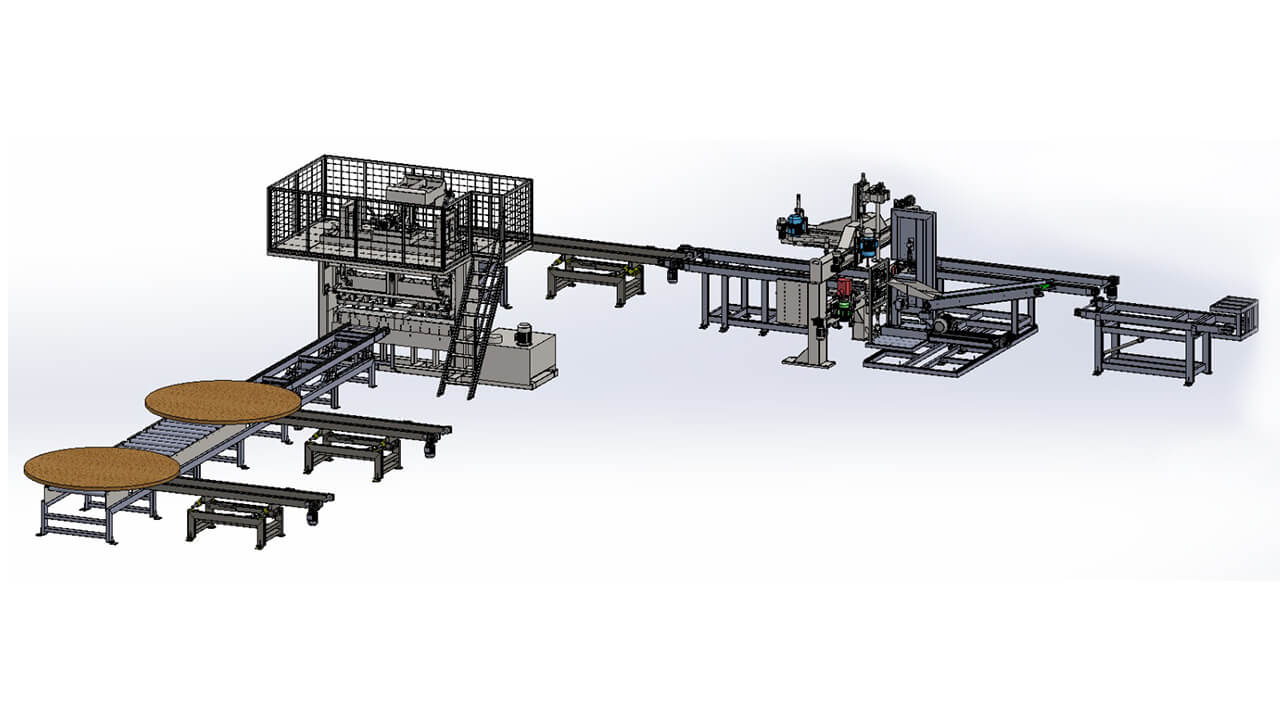

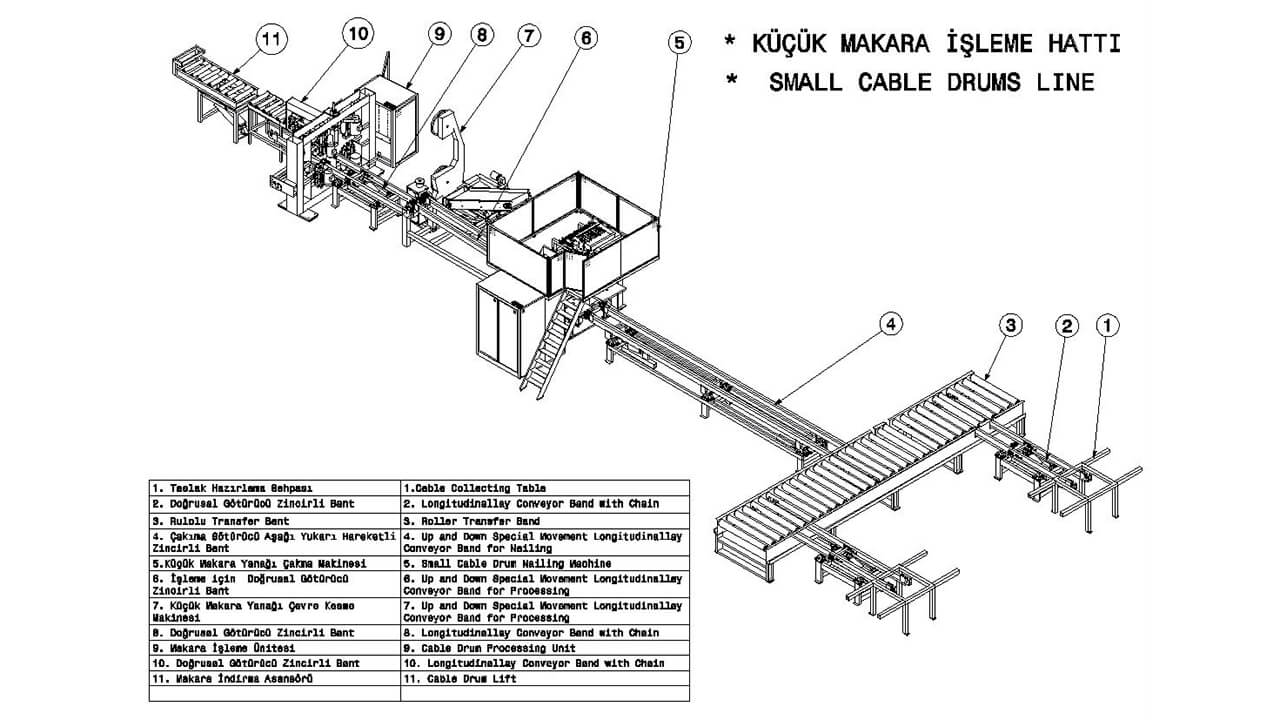

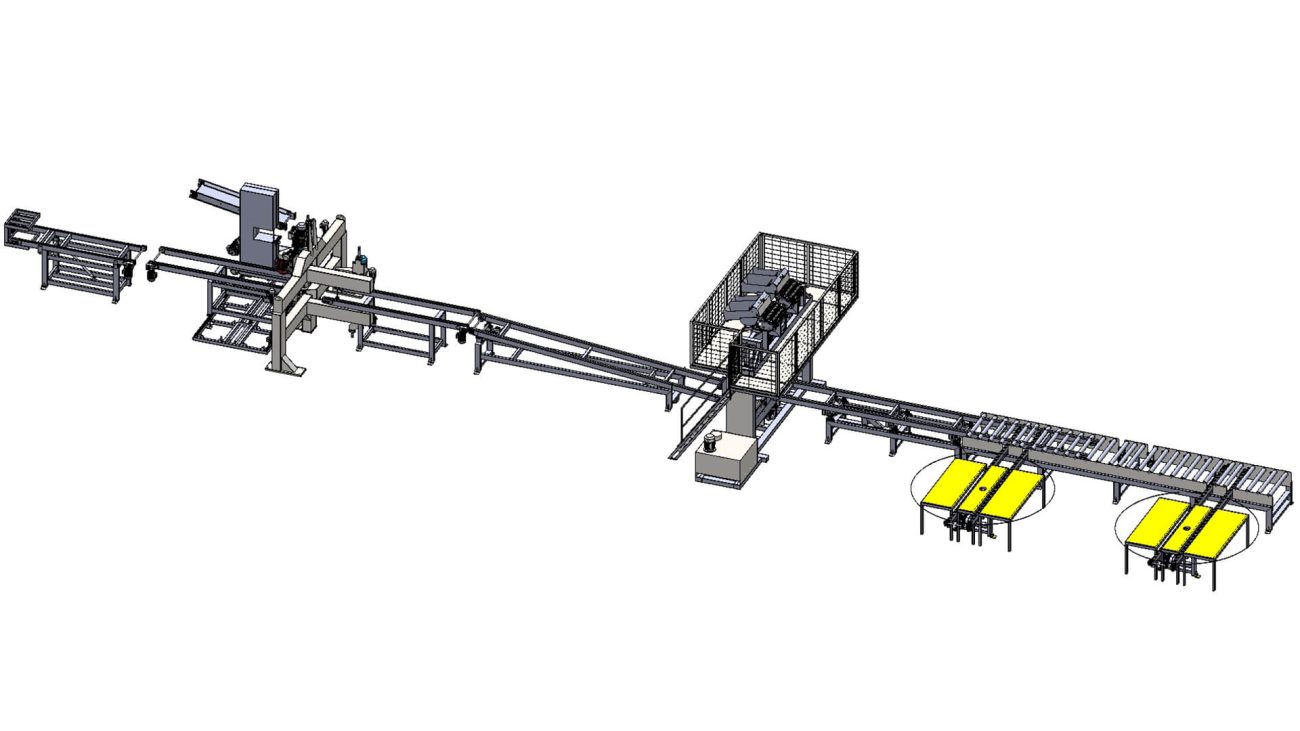

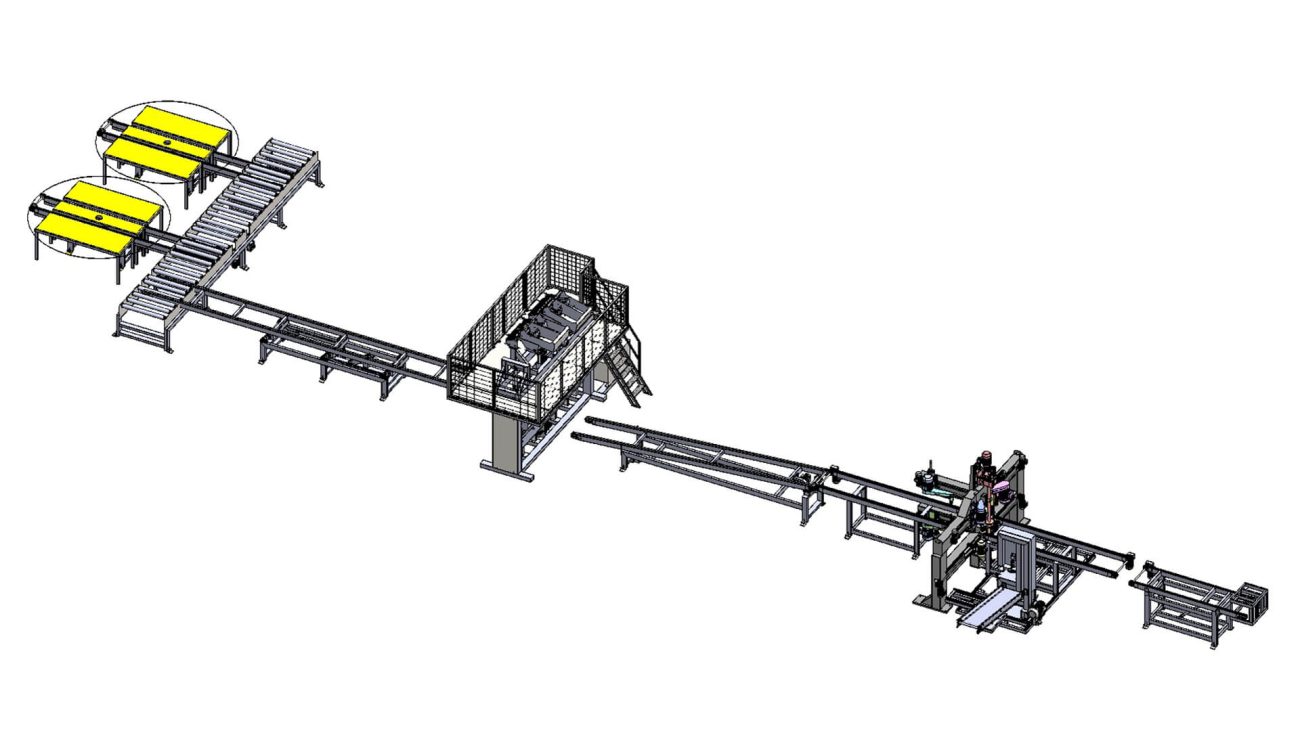

Reel Nailing and Processing Line

In our Reel Fastening and Processing Line production, we have machines working with classical motors that can fasten and process flanges of 600-1600 mm, 800-2500 mm, 800-3200 mm. In addition to these, we also have Reel processing machines with 500-1400 mm and 500-2500 mm capacity working with High Frequency motors.

Categories: Nailing Machine, Woodworking Machine

Description

Technical Information

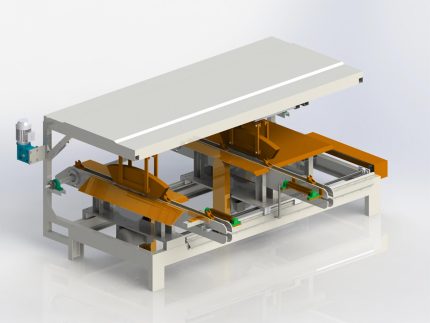

Reel Processing Machine

- Reel Dimensions (Classic Machine): Min 600-800 mm - Max 3200 mm

- Spindle Rotation Speed (Classic Machine): 4800 rpm

- Reel Dimensions (High Frequency Motor): Min 500 mm - Max 2500 mm

- Spindle Rotation Speed (High Frequency Motor): 6,000-12,000 rpm

- Reel Thickness: Min 30 mm - Max 150 mm

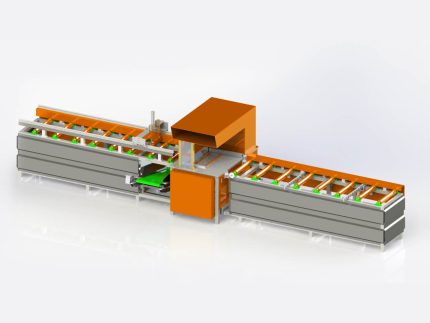

- Perimeter Cutting: Band Saw - P. Milling Machine

- Edge Chamfering: Milling Ball

- Slot Milling: End Mill Cutter

- Rotation / Brake Hole: Blade Drill

- Dowel Hole: Drill Bit

- Cable Exit Hole: Special Milling Cutter

- Central Compression: Hydraulic System

- Flange Surface Cleaning: Brush Sanding System

- Flange Lowering: Tilting Belt

- Flange Transfer: With Chain Belt

Reel Nailing Machine

- Driving Column Movement: Hydraulic System

- Nail Bending Movement: Hydraulic System

- Nail Type Used: Cast Nail

- Nail Delivery System: Pneumatic

- Number of Nail Guns: 24 Pieces

- Number of Nails on the Flange: Adjusted from PLC

- Nail Center Distance: Adjusted Manually

- Flange Diameter: 500 - 3200 mm