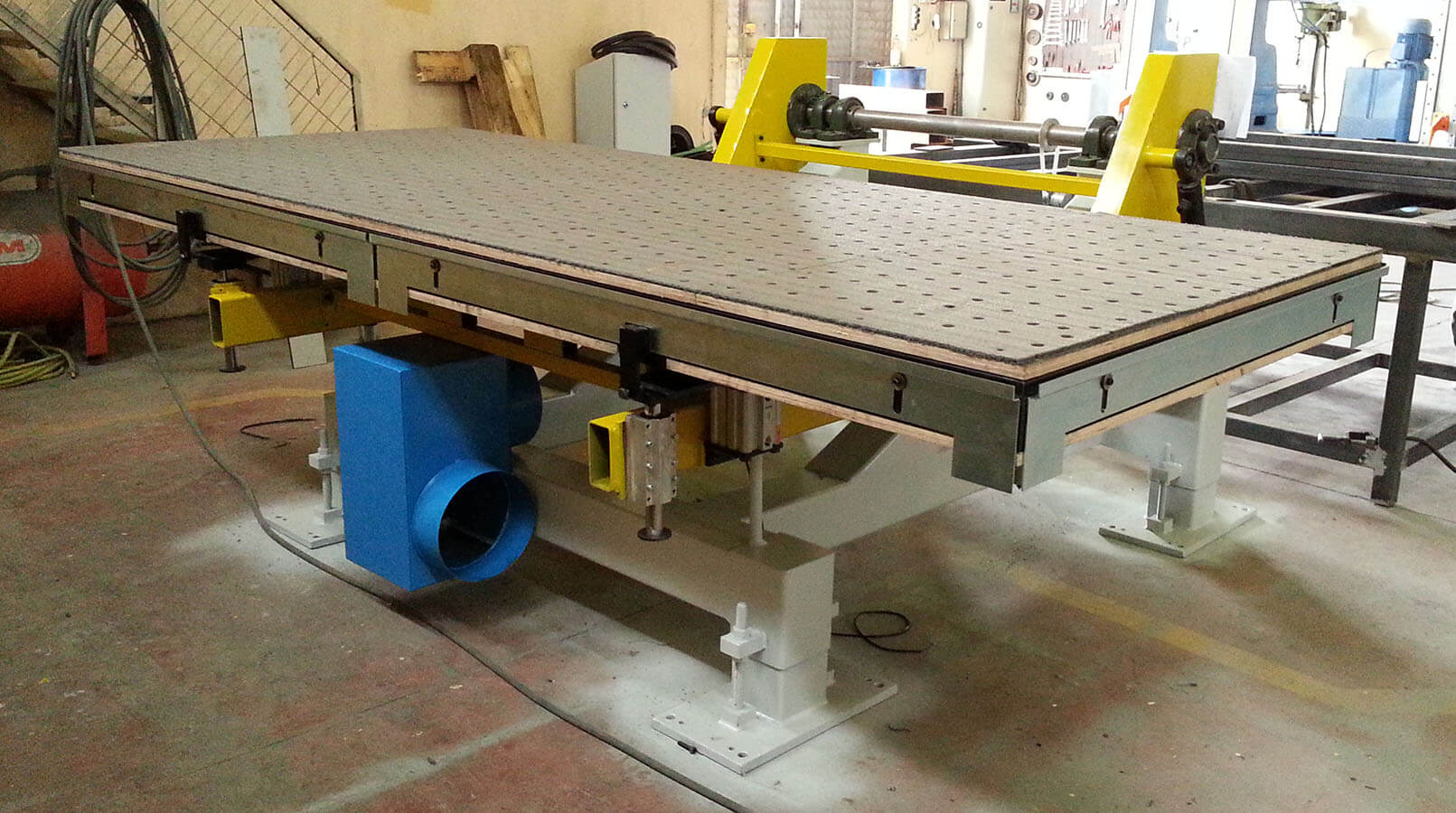

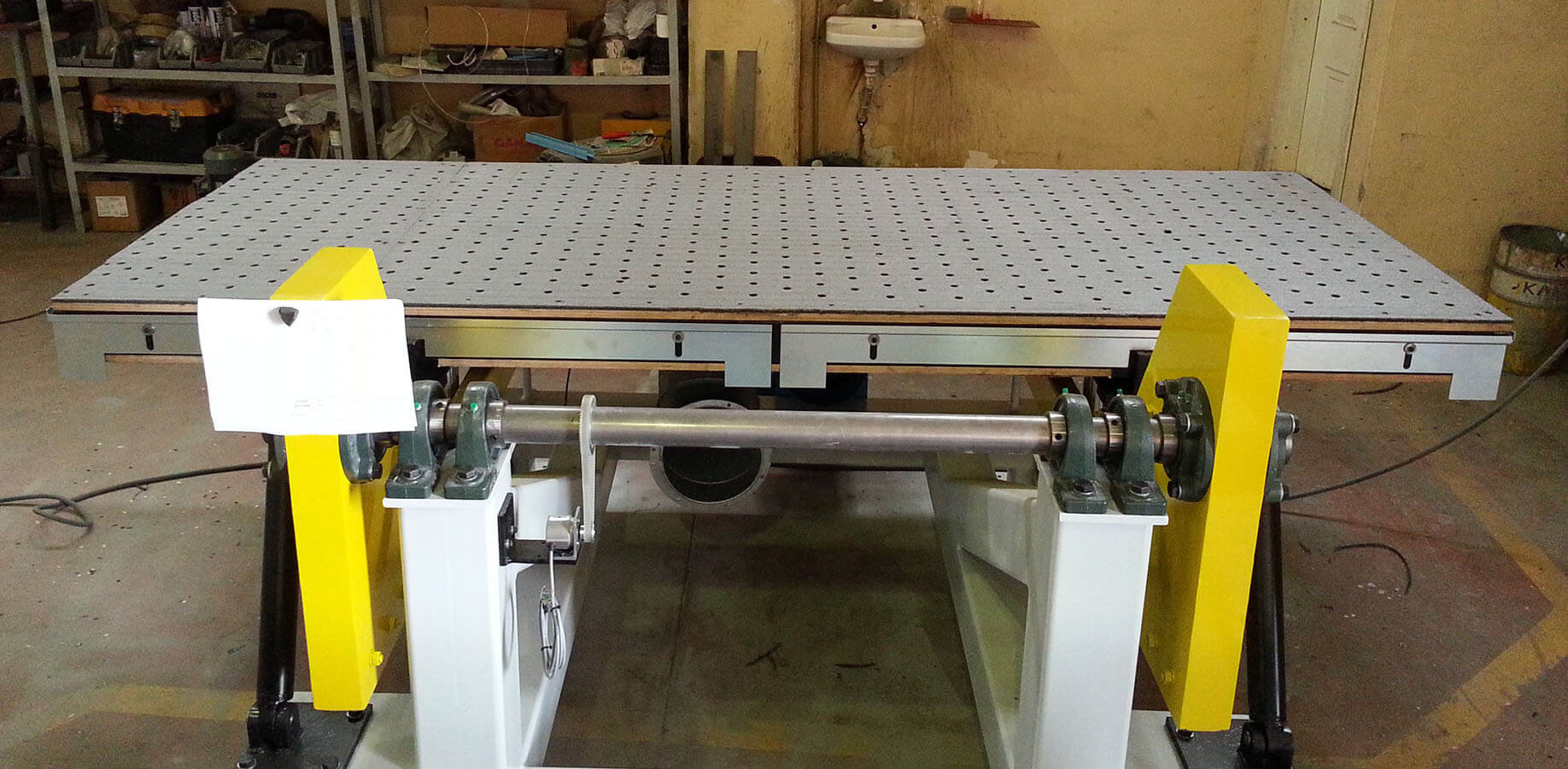

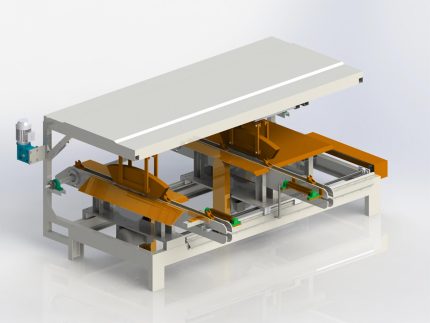

Vacuum Conveying and Inverting Machine

Vacuum Conveying and Reversing Machine is a system developed to quickly empty the printed covers on the table of serial machines such as WEMHOENER and ORMA with pin system and to ensure that the table can be reloaded as soon as possible.

Categories: Cleaning Machine, Furniture Machine

Description

Areas of Use

- Fast emptying of the press table increases daily production capacity and efficiency.

- It is not necessary to cut the covers manually on the table. This prevents the table and pins from being scratched and worn by the cutter.

- All the covers on the table are moved in one move.

- The table is emptied in less than half a minute after leaving the press machine.

- After transportation, the PVC covers will be cleaned and the edges will now be facing upwards.

- This position allows the cleaning blades to easily remove residue without moving the lids. Since there is no additional transportation, this cleaning is done right on the carrier system table, making the total cleaning labor time quite short.

- Not carrying the covers from the press table to the cleaning table or a similar place by hand and not stacking them on top of each other without cleaning the PVC residues will prevent scratches and crushing that may occur on the cover surface and will increase production quality.

- It will also provide economic savings as it will encourage the reduction of the number of employees or their redirection to another task.

- It can be adapted to any machine with an open table.

Technical Information

- Carrier Table Size: Press Machine Table Size - 6 cm

- Vacuum Motor Power: 5.5 kW

- Vacuum Motor Power: 5.5 kW

- Working System: Automatic, Independent of the Press Machine